Laser processing application profession:

(1) at present develops the laser processing the aspect mainly is the elevator, the escalator, the textile machinery, food machinery, the light industry machinery, the refrigerating machinery, the printing mechanism, photocopies the machinery, the transportation machinery, the harbor machinery, the transport machinery, the ships machinery, the agriculture with the machinery, the road machine, transports the machinery, the environmental protection machinery and the mine, the metallurgy machinery and so on the sheet metal processing.

(2) next is the electron, the electric appliance industry including sheet metal processings and so on medical measuring appliance, instrument as well as control cubicle box.

In (3) electrical machinery manufacturing industry each kind of rotor, stator, leaf blade's cutting formation.

In (4) measuring instrument, cutting formations and so on cutting tool industry each kind of saw blade saw blade.

(5) automotive industry including in components, general equipment department synthesis and assembly line part manufacture,

(6) advertisement, decoration and handicraft manufacturing industry.

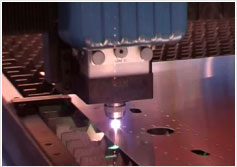

Laser processing characteristic:

The laser processing is the international advanced advanced technique of manufacture, it by “the processing fine, fast, smooth and the province saves on materials” the characteristic is famous.It  does not use the mold.Especially is advantageous to the small batch product components processing and the new product trial manufacturing. does not use the mold.Especially is advantageous to the small batch product components processing and the new product trial manufacturing.

1. cuts the kerf to be thin: Laser cutting kerf generally in 0.10~0.20mm.

2. facets are smooth: Laser cutting facet burr-free, surface roughness generally above Ra:12.5.

3. speeds are quick: The laser cutting speed and the line cut the speed compares must very be quickly many, cuts the 6mm steel plate speed to be possible to amount to together for 1.8 meters/minutes.

4. thermal deformation are small: The laser processing laser kerf thin, the speed quick, the energy is centralized.Therefore passes to is cut on the material the quantity of heat to be small, causes the material distortion extremely to be also small.

5. suits the big-ticket item product the processing: The big-ticket item product mold factory expense is very high, the laser processing does not need any mold manufacture, moreover the laser processing completely avoids nearby collapsing which the material punching shear forms.May reduce the enterprise the production cost to enhance the product large scale the scale.

6. suits the new product extremely the development: Once after the product blueprint forms, may carry on the laser processing immediately.You may obtain the new product material object in the shortest time.

7. saves the material: The laser processing uses the computer programming, may carry on the different shape product the material laying out cloth.Maximum limit enhances the material the use factor.

|